| Correct arrangement of hard pipe piping |

Pay attention to the following points when installing and laying out hard pipe piping:

1. The length of the steel pipe should be short and the diameter of the pipe should be appropriate. Excessive flow rate will lose energy.

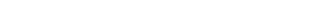

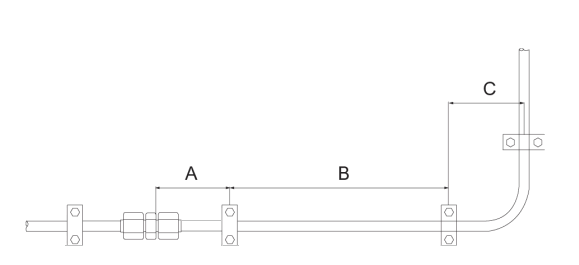

2. The connection between the two fixed points should be avoided tightly, and there must be a loose and bent part. As shown in the figure, it is convenient for loading and unloading, and will not cause serious tensile stress due to thermal expansion and contraction.

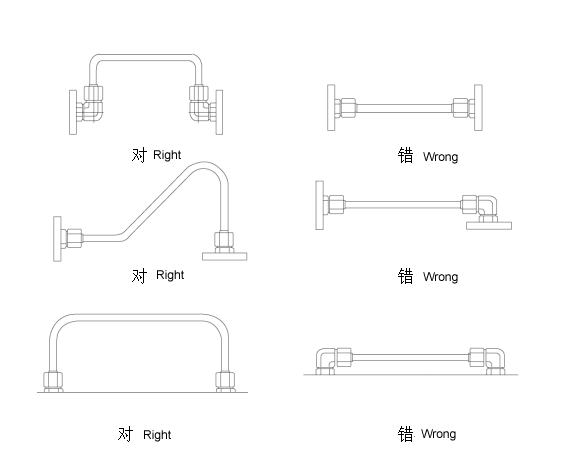

3. The radius of the bend of the steel pipe should be as large as possible, and the radius of the small bend is about 2.5 times the outer diameter of the steel pipe. The straight pipe should be left at the end of the pipe, and the distance should be more than twice the height of the pipe joint nut. as the picture shows

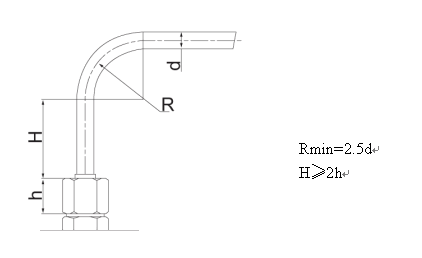

4. The main failure type of hard pipe is fatigue failure caused by mechanical vibration. Therefore, when the pipe is long, pipe clamps are needed to support it, which can not only buffer vibration, but also reduce noise. In pipelines with elbows, support pipe clamps should be added to the straight pipe sections at both ends of the elbow. When connecting with the hose, pipe clamps should be added at the end of the hard pipe for support. The recommended pipe clamp spacing is shown in the figure

5. Do not use too many 90-degree bend steel pipes when avoiding obstacles. The pressure drop of fluid passing through a 90-degree bend pipe is greater than that of two 45-degree bend pipes. As shown

6. When arranging the pipeline, try to keep the pipeline away from the parts that need frequent maintenance. As shown

7. The pipelines should be arranged in an orderly and neat manner to facilitate troubleshooting, maintenance and repair. As shown

|

Next page:Discussion on the Causes of Oil Leakage in Hydraulic System Pipelines and Countermeasures |